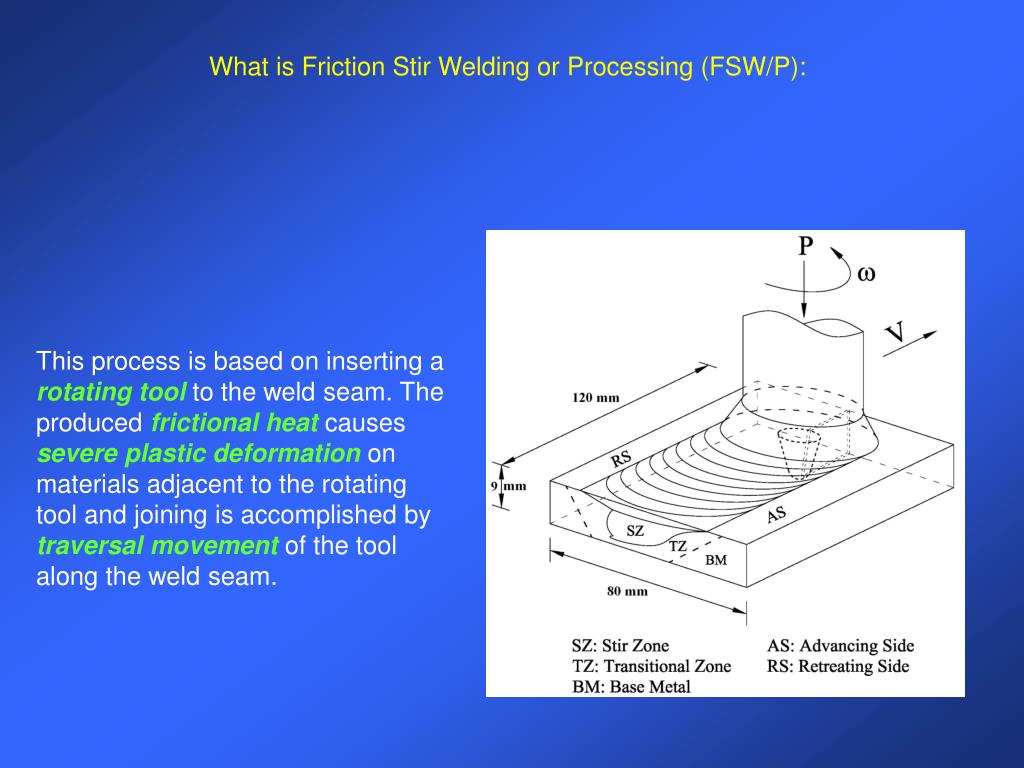

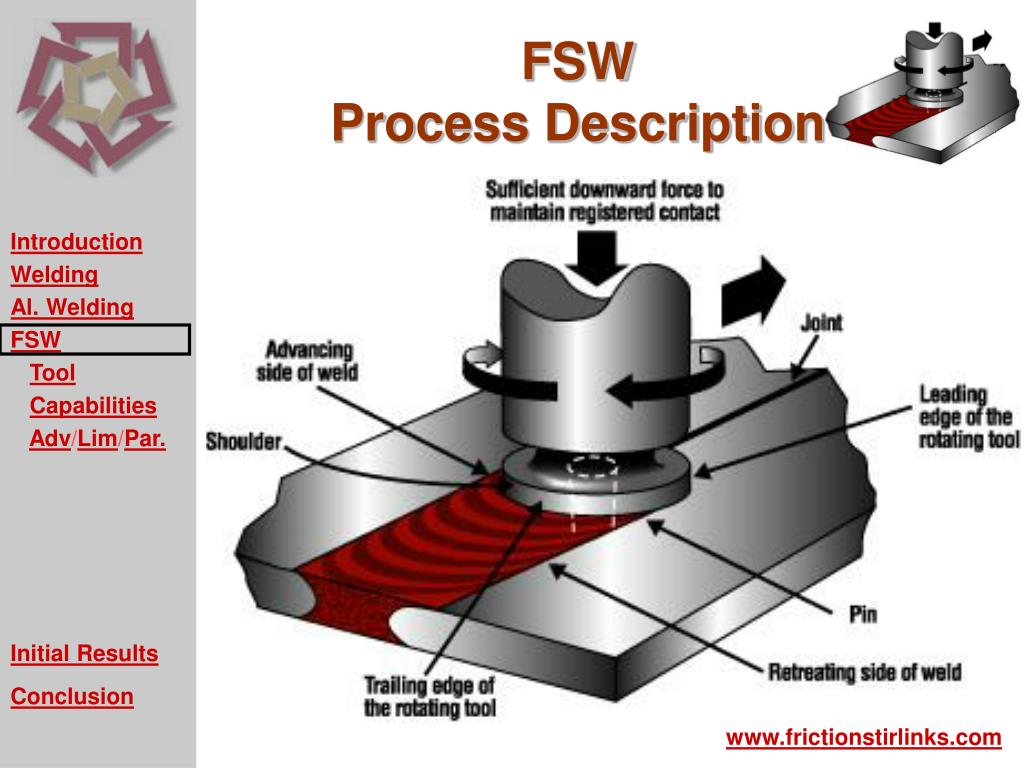

So laser-assisted friction stir welding, which is a potential method to solve the above problem, is put forward. But when FSW is used to join steels and aluminum alloys, some problems that how to intenerate steels and aluminum alloys at the same time, how to minimize the wear of the pin and how to limit the quantity of inter-metallic compounds are supposed to be solved. Friction stir welding (FSW) is extensively used in lightweight metals such as titanium alloys and aluminum alloys. The brittle intermetallic compounds have a great effect on the performance of the welding joint. Besides, it is unavoidable to produce brittle intermetallic compounds at the interface of aluminum alloys and steel by using the above conventional welding ways to connect aluminum alloys and steels. The main reason is that big differences of thermophysical properties exist between steels and aluminum alloys. But it is hard to get a good joint between steels and aluminum alloys if used by conventional welding ways such as explosion welding, ultrasonic welding, laser welding and friction welding.

Results show that the welding temperature has a significant effect on the microstructures and the mechanical properties of the joint.Īt present, the use of combining steel and aluminum has been introduced to the shipbuilding, aerospace and automobile industries because it can reduce the weight themselves to improve fuel efficiency and energy preservation. What is more, SEM, hardness test and an optical microscope are used to analyze the fractography of tensile fracture surfaces, hardness profile and the metallographic structure of the joints, respectively.

Proper laser power can obtain a sound joint. It indicates that laser power is one of the key factors that affect the tensile strength of the joints significantly. Besides, the temperature field of wok-piece was calculated at different laser powers and the corresponding tensile strength of the joints were tested and compared. The measured result is in good with the calculated result. The temperature field is measured by infrared thermography and it is compared with the simulated result under the same condition. The mathematical model of heat source, which is from the laser beam, the tool shoulder and the tool pin, is developed respectively.

Laser-assisted friction stir welding between Q235 steel and 6061-T6 aluminum alloy was studied by numerical and experimental methods in this paper.

0 kommentar(er)

0 kommentar(er)